10 Digital Best Practices for Enhancing Your Buck Converter Efficiency

In the rapidly evolving landscape of power electronics, optimizing the efficiency of buck converters has become a critical focus for engineers and designers aiming to meet the increasing demands for energy efficiency and performance. According to a recent report by the International Energy Agency (IEA), power losses in electronic devices account for nearly 15% of global electricity consumption, emphasizing the need for enhanced converter performance. Buck converters, which are widely utilized in applications ranging from consumer electronics to electric vehicles, can significantly influence overall system efficiency. By adopting best practices in design and implementation, it's possible to reduce power losses and improve conversion efficiencies, ultimately leading to more sustainable and efficient energy solutions. As we delve into ten digital best practices tailored for enhancing buck converter efficiency, we'll explore how these strategies can help professionals stay ahead in a competitive market while contributing to a greener future.

Understanding the Basics of Buck Converter Efficiency Optimization

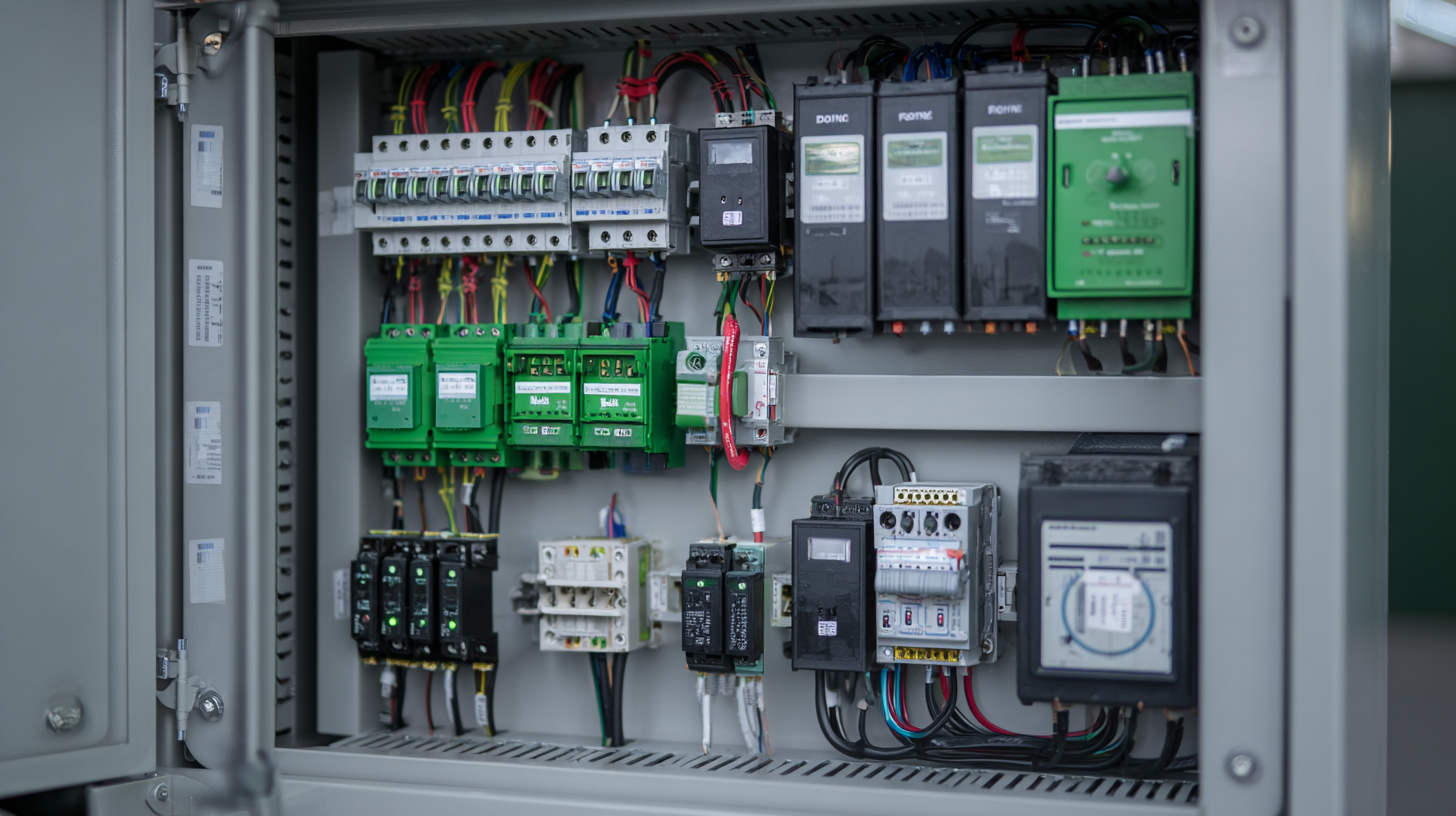

When it comes to optimizing the efficiency of a buck converter, understanding the foundational principles is essential. At its core, a buck converter functions by stepping down voltage while maintaining energy efficiency. The primary factors influencing its performance include switching losses, conduction losses, and the overall design of the circuit. By grasping these basics, engineers can implement strategies to enhance converter efficiency significantly.

One of the key methods for improving buck converter efficiency lies in selecting the right components. High-quality MOSFETs with low on-resistance and fast switching speeds can reduce losses during operation. Additionally, optimizing the layout of the circuit to minimize parasitic inductance and capacitance is crucial. This careful design consideration not only maximizes energy transfer but also reduces the heat generated, thereby extending the lifespan of the components. Furthermore, incorporating advanced control techniques such as adaptive voltage positioning and synchronous rectification can lead to substantial performance improvements in buck converters, making them more efficient and reliable in various applications.

10 Digital Best Practices for Enhancing Buck Converter Efficiency

This chart illustrates the key parameters that affect the efficiency of a buck converter, showcasing input voltage, output voltage, load current, switching frequency, and the resulting efficiency percentage. By optimizing these parameters, enhanced performance can be achieved.

Key Factors Affecting Buck Converter Performance in Digital Applications

When it comes to improving the efficiency of buck converters in digital applications, several key factors come into play. One of the most significant influences is the choice of controller topology. Synchronous rectification, for instance, can reduce conduction losses significantly compared to traditional diode-based designs. This improvement can lead to higher efficiency, especially under varying load conditions. Properly selecting the controller also allows for better voltage regulation and transient responses, which are critical for digital devices that demand stable performance.

Another crucial aspect is inductor selection. The inductor not only affects efficiency but also impacts ripple current and electromagnetic interference (EMI). Using inductors with low DC resistance can minimize losses, while ensuring that the inductor's current rating meets the system's requirements is essential for reliability. Additionally, the layout of the PCB plays a substantial role. A well-designed layout that minimizes parasitic inductances can improve performance and efficiency by allowing for faster switching speeds and reduced noise, ultimately enhancing the buck converter's capability in digital applications.

Advanced Control Techniques for Improved Buck Converter Efficiency

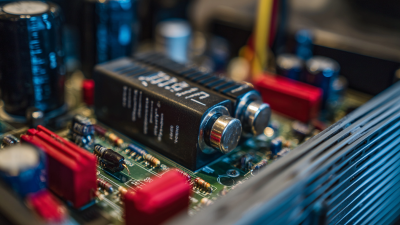

Advanced control techniques play a pivotal role in enhancing the efficiency of buck converters, a crucial component in modern power management systems. According to a report by the International Energy Agency (IEA), improving the efficiency of power converters can lead to energy savings of up to 30% in electronic devices. Implementing advanced control strategies, such as adaptive control algorithms and model predictive control, can dynamically adjust the operating conditions of buck converters, minimizing losses associated with switching and conduction.

Tip: Consider integrating adaptive control techniques that respond to variations in load and input voltage. This responsiveness can significantly reduce energy waste, offering a more stable and efficient power conversion process.

Furthermore, utilizing digital controllers with enhanced algorithms enables the precise modulation of switching frequency and duty cycle. A study from the IEEE Power Electronics Society indicates that advanced digital control can achieve efficiency levels above 95% in high-performance applications. By employing real-time data processing and feedback systems, designers can optimize the performance and reliability of buck converters in various applications.

Tip: Invest in high-performance digital signal processors (DSPs) that can handle complex algorithms with minimal latency. This investment can result in a noticeable improvement in both efficiency and system response time.

10 Digital Best Practices for Enhancing Your Buck Converter Efficiency

| Best Practice | Description | Impact on Efficiency | Implementation Complexity |

|---|---|---|---|

| Adaptive Voltage Positioning | Adjusts output voltage based on load changes to improve regulation. | High | Medium |

| Digital PID Control | Utilizes digital PID controllers for precise output management. | Very High | High |

| Synchronous Rectification | Replaces diodes with MOSFETs to reduce conduction losses. | High | Medium |

| Soft Start Mechanism | Gradually ramps up output voltage to minimize inrush current. | Low | Low |

| Pulse Frequency Modulation | Adjusting the switching frequency to manage efficiency based on load. | Medium | Medium |

| Dynamically Adjusted Duty Cycle | Changes duty cycle dynamically according to load conditions. | High | Medium |

| Input Voltage Feedforward | Incorporates input voltage variations into the control loop. | High | High |

| Flyback Energy Recovery | Recovering energy from the flyback inductor to improve efficiency. | Very High | High |

| Thermal Management Techniques | Implementing strategies to manage heat dissipation effectively. | High | Medium |

Practical Tips for Minimizing Losses in Buck Converter Designs

When designing buck converters, minimizing losses is crucial for enhancing overall system efficiency. According to a report by the International Energy Agency (IEA), power conversion losses constitute up to 15% of total system inefficiencies in various applications. To address this, one effective practice is to select high-performance MOSFETs with low RDS(on) values, as this can significantly reduce conduction losses during operation. Advanced devices are now available that boast RDS(on) values below 5 milliohms, which can lead to a substantial decrease in power loss, especially at higher load currents.

When designing buck converters, minimizing losses is crucial for enhancing overall system efficiency. According to a report by the International Energy Agency (IEA), power conversion losses constitute up to 15% of total system inefficiencies in various applications. To address this, one effective practice is to select high-performance MOSFETs with low RDS(on) values, as this can significantly reduce conduction losses during operation. Advanced devices are now available that boast RDS(on) values below 5 milliohms, which can lead to a substantial decrease in power loss, especially at higher load currents.

Another essential factor is the optimization of the inductor design. Studies show that the choice of inductor material and winding technique can influence core losses, which represent a significant portion of total losses in inductive components. Shielded inductors utilizing ferrite materials can minimize these core losses, and employing proper winding geometries can offer better performance. A recent analysis indicated that using optimized inductors can enhance efficiency by approximately 8% in typical buck converter applications. Thus, focusing on component selection and design strategies is vital for engineers aiming to improve the efficiency of their buck converter systems.

Tools and Technologies for Analyzing Buck Converter Performance

When it comes to enhancing buck converter efficiency, the right tools and technologies play a pivotal role in assessing performance and making informed improvements. One essential tool is the digital oscilloscope, which captures voltage and current waveforms in real time, allowing engineers to visualize switching events and efficiency losses. By analyzing these waveforms, you can identify potential issues such as excessive ringing, voltage spikes, or suboptimal duty cycles that may be hindering efficiency.

Another valuable technology is simulation software, which enables engineers to model buck converter performance under various conditions. Using tools like SPICE or dedicated power electronics simulation platforms, designers can test different component values, switching frequencies, and control strategies before physical implementation. This reduces prototyping time and costs, while ensuring that the design is optimized from the outset. Additionally, employing thermal imaging cameras can help monitor thermal performance during operation, offering insights into hotspots and enabling adjustments that bolster overall efficiency. By leveraging these advanced tools and technologies, engineers can significantly enhance the efficiency of their buck converters, leading to more reliable and effective power management solutions.

Related Posts

-

5 Essential Tips to Optimize Your UPS Electrical Systems for Maximum Efficiency

-

Understanding the Differences in Power Supply Unit Technologies

-

5 Proven Reasons High Voltage DC DC Converters Are Essential for Modern Power Systems

-

Innovative Applications of DC to DC Converters in Modern Electronics

-

7 Reasons Why AC to DC Inverters Are Essential for Your Business Efficiency

-

10 Best DC to DC Converters You Should Consider For Your Next Project

At Premium PSU, we are specialists in designing and manufacturing power conversion systems for the industrial market. Our product range includes high reliability power supplies from 50W to 72kW.

PREMIUM PSU

C/ Dolors Aleu, 19-21, 2nd Floor

08908 – Hospitalet de Llobregat

Barcelona-SPAIN

t.+34 93 223 26 85