10 Essential Tips for Understanding and Using Buck Converters Effectively

In the realm of power electronics, buck converters have emerged as a critical technology for efficiently stepping down voltage in a variety of applications. According to a report by MarketsandMarkets, the global power electronics market is projected to reach USD 1 trillion by 2026, highlighting the increasing demand for advanced power management solutions. As energy efficiency becomes a key focus in modern electronic design, buck converters are pivotal in minimizing power loss and enhancing overall system performance.

Despite their widespread use, many engineers and designers may encounter challenges in effectively implementing buck converters. A recent survey conducted by the Electric Power Research Institute (EPRI) revealed that close to 40% of electronic failures can be attributed to improper converter design and selection. Understanding the fundamental principles and best practices related to buck converters is essential for both novice and experienced engineers alike. This article presents ten essential tips for mastering the intricacies of buck converters, ultimately empowering users to optimize their designs and achieve superior energy efficiency.

Understanding the Basics of Buck Converters and Their Applications

Buck converters, also known as step-down converters, are essential components in many modern electronic systems, particularly in power management applications. By transforming a higher input voltage to a lower output voltage with high efficiency, they minimize energy loss and thermal management issues. According to a report by MarketsandMarkets, the global buck converter market is projected to grow from $2.5 billion in 2020 to $4.1 billion by 2025, showcasing their increasing importance in sectors ranging from consumer electronics to automotive and renewable energy systems.

A fundamental understanding of buck converters involves grasping the core principles of switching regulation. These devices typically operate using a high-frequency switching element (such as a transistor) regulated by a control mechanism to maintain a steady output voltage despite variations in load and input voltage. The efficiency of a buck converter can exceed 90%, making them ideal for applications requiring battery management and efficient power supply.

Insight from the International Energy Agency highlights that implementing advanced power conversion designs, including buck converters, can result in up to a 30% reduction in energy consumption across various sectors. With their diverse applications, including in LED drivers and electric vehicle systems, grasping the underlying mechanisms of buck converters paves the way for innovations in energy-efficient technologies.

Key Components of Buck Converters: What You Need to Know

When delving into buck converters, understanding their key components is crucial for effective application. At the heart of a buck converter lies the switch, which can be a transistor, typically MOSFET. This component plays a vital role in regulating the output voltage by rapidly opening and closing, allowing energy to flow in pulses. The performance of the switch significantly affects the converter's efficiency and heat generation. Proper selection of the switch will ensure optimal energy transfer and overall system reliability.

Another essential component is the inductor, which stores energy during the "on" phase of the switch. The inductance value must be chosen carefully to balance between size, efficiency, and performance. A higher inductance typically leads to lower ripple current and smoother output voltage, but it also increases the size and cost of the converter. Moreover, the output capacitor also plays a fundamental role. It smooths the voltage output, reducing voltage ripple, and ensuring stable operation under varying load conditions. The choice of capacitance and voltage rating must align with the converter's requirements for optimal performance. Understanding these components will empower designers to utilize buck converters effectively in their applications.

How to Calculate Efficiency and Performance of Buck Converters

When working with buck converters, understanding their efficiency and performance is crucial to their effective application. One key aspect to consider is how to calculate the efficiency of a buck converter. Efficiency can be defined as the ratio of output power to input power, typically expressed as a percentage. To calculate it, one can use the formula: Efficiency (%) = (Output Voltage × Output Current) / (Input Voltage × Input Current) × 100 . Monitoring these parameters helps in identifying the operating conditions that lead to optimal performance.

To enhance the understanding of buck converters, here are a few essential tips. First, always consider the switching frequency. Higher frequencies can reduce the size of passive components but may lead to efficiency losses due to increased switching losses. Second, selecting the right inductance value is vital. A properly sized inductor can minimize ripple current and maintain high efficiency across different load conditions. Lastly, ensure that your layout minimizes EMI (electromagnetic interference) and thermal losses; a well-designed PCB can significantly improve both performance and reliability.

In addition to these tips, conducting thermal analysis can provide insights into how well your buck converter is performing under various loads. By calculating thermal efficiency, which includes power dissipation due to heat generation, you can fine-tune the design for better overall efficiency and longevity. Employing these techniques will significantly enhance your ability to use buck converters effectively in your projects.

Common Challenges in Buck Converter Design and How to Overcome Them

When designing buck converters, engineers often encounter several common challenges that can impact performance and efficiency. One significant issue is ripple voltage, which can lead to noise and instability in the output signal. To mitigate this, it's essential to implement proper filtering techniques, such as using low ESR capacitors and a well-designed inductor. Increasing the capacitance value and enhancing the inductor quality can also help in reducing ripple, ensuring a stable output voltage that meets the target specifications.

Another prevalent challenge is thermal management. Buck converters typically generate heat, which can affect their efficiency and longevity. To combat this, careful layout design is crucial; ensuring sufficient spacing and using appropriate heat sinks can significantly improve thermal dissipation. Additionally, selecting components with lower on-resistance and higher efficiency ratings can help minimize heat generation during operation. By addressing these challenges with targeted strategies, engineers can enhance the performance and reliability of their buck converters, ultimately leading to a more robust design.

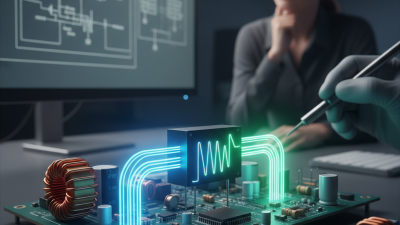

Best Practices for Testing and Troubleshooting Buck Converters

When it comes to testing and troubleshooting buck converters, understanding the operational principles is crucial to ensure optimal performance. A buck converter’s efficiency often hinges on its design and component selection, which can significantly impact real-world performance. According to a report by the International Energy Agency (IEA), improperly managed power conversion can lead to energy losses exceeding 10%. Therefore, implementing thorough testing protocols is essential. Utilizing tools such as oscilloscopes and multimeters allows engineers to monitor output voltage and ripple, which can indicate potential issues in the conversion process.

Furthermore, adopting best practices in troubleshooting can enhance the reliability of buck converters. Regularly checking for thermal management is vital, as excessive heat can degrade performance and lifespan. A study by the IEEE reveals that thermal issues are responsible for nearly 30% of power electronics failures. Additionally, ensuring proper layout in PCB design can minimize parasitic inductance and capacitance, leading to improved stability. By establishing a systematic approach to testing—such as verifying component ratings, inspecting solder joints, and assessing input supply quality—engineers can greatly improve the functionality and durability of buck converters across various applications.

Related Posts

-

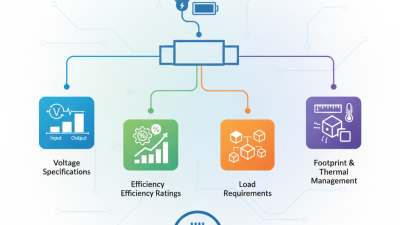

How to Select the Best Buck Converter for Efficient Power Management in Your Application

-

Exploring the Future of Buck Converters at China's 138th Canton Fair 2025: Industry Insights and Innovations

-

10 Digital Best Practices for Enhancing Your Buck Converter Efficiency

-

Unlocking Efficiency: How Buck Converters Achieve Over 95% Power Conversion in Modern Electronics

-

What is a Buck Converter? Understanding Its Function and Applications

-

How to Choose the Right DC Converter for Your Project Needs

At Premium PSU, we are specialists in designing and manufacturing power conversion systems for the industrial market. Our product range includes high reliability power supplies from 50W to 72kW.

PREMIUM PSU

C/ Dolors Aleu, 19-21, 2nd Floor

08908 – Hospitalet de Llobregat

Barcelona-SPAIN

t.+34 93 223 26 85