How to Select the Right AC to DC Converter for Your Specific Needs

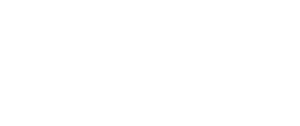

Selecting the right AC to DC converter is crucial for optimizing performance in various applications, from consumer electronics to industrial machinery.

According to a recent report by MarketsandMarkets, the global AC-DC power supply market is projected to grow at a CAGR of 5.4% from 2021 to 2026, highlighting the increasing demand for efficient power solutions.

With advancements in technology, AC to DC converters are becoming more compact and sophisticated, catering to specific needs in sectors such as renewable energy and electric vehicles.

Understanding different converter types, their efficiencies, and application requirements is essential for engineers and project managers alike.

This guide aims to demystify the selection process for AC to DC converters, helping you make informed choices that align with both performance and economic priorities.

With advancements in technology, AC to DC converters are becoming more compact and sophisticated, catering to specific needs in sectors such as renewable energy and electric vehicles.

Understanding different converter types, their efficiencies, and application requirements is essential for engineers and project managers alike.

This guide aims to demystify the selection process for AC to DC converters, helping you make informed choices that align with both performance and economic priorities.

Understanding Your Power Requirements for AC to DC Conversion

When selecting the right AC to DC converter, understanding your power requirements is crucial, especially in today's rapidly evolving technological landscape. Data centers, for instance, are at the forefront of the AC versus DC debate as they adapt to the increasing demands of high-density computing. The recent push for 800V high voltage DC power distribution highlights the industry's shift towards more efficient energy use, essential for supporting advanced processing racks. Recognizing your specific needs—whether for data centers or other applications—can guide you in choosing the appropriate converter that maximizes performance and minimizes costs.

**Tips:** Always assess the total power capacity and voltage requirements of your devices before making a selection. Consider the input power quality, as it can significantly impact the efficiency and reliability of the conversion process. Additionally, don't overlook the importance of harmonics; optimizing total harmonic distortion (THD) in your AC-DC conversion can enhance the overall system performance and prolong the lifespan of your equipment. With a clear understanding of your power needs, you can make informed decisions about which AC to DC converter will best serve your specific applications.

Identifying the Applications: Where Will the Converter Be Used?

When selecting an AC to DC converter, understanding the applications where it will be utilized is crucial for making the right choice. Different environments and devices require tailored solutions. For example, a home appliance might have different voltage and current requirements compared to industrial machinery. Knowing these specifics allows you to pick a converter that not only fits the power needs but also ensures safety and efficiency.

**Tips:** Always start by assessing the voltage and current specifications of your application. Consider factors like load changes and potential power surges. Make sure the converter can handle fluctuations in the power supply to maintain consistent performance. Additionally, review the environmental conditions it will face—some converters need protection against dust, humidity, or extreme temperatures.

Moreover, think about the converter's footprint and design. In compact electronic devices such as smartphones, space is at a premium. A smaller, integrated converter can be beneficial, while larger systems may have more flexibility. Be mindful of efficiency ratings as well, as a more efficient converter can lead to lower operational costs and heat generation.

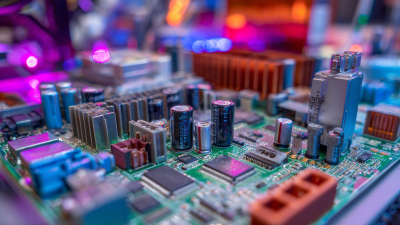

Evaluating Efficiency Ratings and Performance Metrics

When selecting an AC to DC converter, evaluating efficiency ratings and performance metrics is crucial for ensuring optimal operation. Efficiency ratings indicate how much of the input power is converted into usable output power, typically expressed as a percentage. Industry reports suggest that a high-efficiency converter can achieve ratings of over 90%, significantly reducing energy losses and overall operational costs. For example, the U.S. Department of Energy reported that improving conversion efficiency by just 1% can lead to substantial savings for large-scale applications such as data centers.

One important performance metric to consider is the load regulation, which assesses a converter's ability to maintain constant output voltage under varying load conditions. A low load regulation value signifies better performance, providing stable voltage without fluctuations, which is essential for sensitive electronic devices. According to the International Energy Agency (IEA), converters with superior load regulations can enhance the lifespan and reliability of downstream electronics.

Tips: Always check for industry certifications such as Energy Star or UL compliance, as these can be indicators of the converter's efficiency and safety. Additionally, consider the operating temperature range and the converter's thermal management capabilities to prevent overheating, which can reduce performance and longevity.

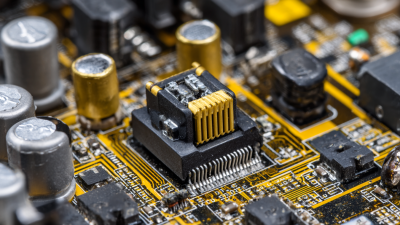

Key Features to Consider: Size, Weight, and Cooling Methods

When selecting an AC to DC converter, key features such as size, weight, and cooling methods play a critical role in ensuring the device meets your application requirements. Size is paramount; a compact converter is often essential for portable devices or applications with limited space. Conversely, larger converters may accommodate higher power outputs, making them more suitable for industrial uses. Evaluating the dimensions helps ensure the converter integrates seamlessly into your existing setup.

Weight is another vital consideration, particularly in mobile applications where excessive weight can affect performance and usability. Lightweight converters ease transportation and installation, enhancing the overall efficiency of the system. Lastly, cooling methods must be assessed. Depending on the power levels and ambient conditions, converters might require passive or active cooling solutions. Passive cooling utilizes natural convection, making it suitable for low-power applications, while active cooling, employing fans or liquid systems, is ideal for high-output converters where heat dissipation is crucial. Balancing these features will guide you in selecting a converter that optimally aligns with your specific needs.

How to Select the Right AC to DC Converter for Your Specific Needs - Key Features to Consider

| Feature | Description | Importance | Example Values |

|---|---|---|---|

| Size | Physical dimensions of the converter which can affect installation and space utilization. | Critical for compact designs. | 50mm x 30mm x 15mm |

| Weight | The total weight of the converter, influencing transport and mounting options. | Important for portable devices. | 200 grams |

| Cooling Method | Technique used to dissipate heat generated during operation, such as passive or active cooling. | Essential for reliability and longevity. | Passive Cooling, Active Cooling with Fans |

| Input Voltage Range | The acceptable range of AC input voltage for the converter. | Determines compatibility with power sources. | 100V - 240V AC |

| Output Power Rating | The maximum power output the converter can deliver. | Critical for selecting converters for load requirements. | 100W, 250W |

Budgeting for Quality: Finding the Right Balance Between Cost and Performance

When selecting an AC to DC converter, budgeting for quality becomes a crucial factor. The goal is to find the right balance between cost and performance, as a cheaper option may lead to inefficiencies and higher operational expenses in the long run. Recent industry reports suggest that investing in high-quality converters can result in improved energy efficiency, potentially saving up to 30% on energy costs compared to lower-tier models.

Tips: Always assess your specific needs based on voltage and current ratings. Conduct thorough research on both the manufacturer’s credibility and customer reviews to ensure reliability. Additionally, consider the lifecycle costs associated with the product, including potential downtime or increased maintenance associated with cheaper alternatives.

As seen in the technological sector, where companies are innovating solutions like AI models with adjustable performance costs, the same principle applies to AC to DC converters. By evaluating the performance capabilities against the budget, you can align your purchase with your operational goals without compromising on quality. Aim for options that offer flexibility without the pitfalls of lower performance due to cost-saving measures.

Related Posts

-

How to Select the Best Buck Converter for Efficient Power Management in Your Application

-

Exploring DC DC Converter Innovations at the 138th Canton Fair 2025 in China

-

Exploring the Future of Buck Converters at China's 138th Canton Fair 2025: Industry Insights and Innovations

-

Exploring UPS Electrical Innovations at the 138th Canton Fair China 2025

-

7 Reasons Why AC to DC Inverters Are Essential for Your Business Efficiency

-

Exploring ATX Power Supply Innovations at the 138th Canton Fair 2025: Industry Insights and Trends

At Premium PSU, we are specialists in designing and manufacturing power conversion systems for the industrial market. Our product range includes high reliability power supplies from 50W to 72kW.

PREMIUM PSU

C/ Dolors Aleu, 19-21, 2nd Floor

08908 – Hospitalet de Llobregat

Barcelona-SPAIN

t.+34 93 223 26 85